Not shocked at all

-

In fact, I'm chuffed.

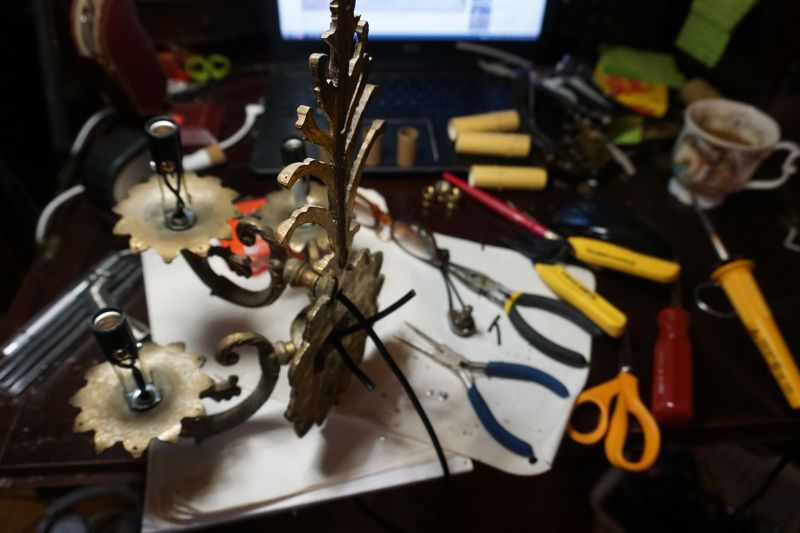

Years ago, I bought a skeleton of a wall sconce. All the wiring had been gutted, so I used it with reall candles for a while. Then it ended up in the upstairs stair well gathering dust.

About three weeks ago I was needing a sconce and it dawned on me that I could wire up that old skeleton that hadn't really done much all these years. So I ordered the parts online: sockets, insulators, candle sleeves, wire, and a rotary switch. I bought a cheapo soldering iron and solder at the hardware store.

The hardest part was getting the wire through the arms. Oh my gosh. Finally found that picture hanging wire had just enough stiffness and enough flexibility to go through. I taped the electrical wire to an end of it and a combination of pushing and pulling got them wired.

I blew the circuit breaker twice because I didn't understand the switch. I was expecting one with a black wire and a white wire. This one had two black wires and they were both smooth. A bit of poking around the webs and I soon realized that the switch is in-line on the hot wire (similar to those thumb wheels that one can install on a lamp cord). So a quick switcheroo of wiring and no more blown breaker.

I need to investigate soldering because that was not a very smooth process for me. The solder would take a while to melt (even though the iron was on for some time) and then would ball up and roll right off the wires. I think I need a variable temperature iron and maybe better quality solder. (I did use resin core as is stipulated for electrical wiring.)

Anyhoo, I'm very happy with how it turned out and it works! I need to go get decent bulbs for it this weekend because the ones have are far too bright.

-

@Bernard You're very talented and brave.

I guess it was because of being raised by an electrician and maternal grandparents who were raised without electricity combined with my lack of being mechanically inclined that I won't try any project involving electricity.

The breaker box for this mobile home is in roommate's bedroom and he had a lock on his door for months. It infuriated me. I wouldn't have been able to plan what you just did let alone follow through with it.

Congrats on your project! It's beautiful.

-

Very nice!

-

Flux - Even though you used the rosin core solder, it is very helpful to clean the wires and soldering iron tip first so that the solder draws onto the surface instead of beading up. My dad used to tell me to "tin the wires first" - then a quick touch with the iron when twisted together and perhaps a bit more solder makes for a quick and neat joint.

(I would combinations of paste and liquid acid flux when working on brass instruments depending on the situation)

-

What Ron said.

️

️Also on solder, you have to get the wires hot enough to melt the solder by themselves. Heating just the solder won’t work.

-

Flux - Even though you used the rosin core solder, it is very helpful to clean the wires and soldering iron tip first so that the solder draws onto the surface instead of beading up. My dad used to tell me to "tin the wires first" - then a quick touch with the iron when twisted together and perhaps a bit more solder makes for a quick and neat joint.

(I would combinations of paste and liquid acid flux when working on brass instruments depending on the situation)